Contact

If you have any questions, don't hesitate to contact us

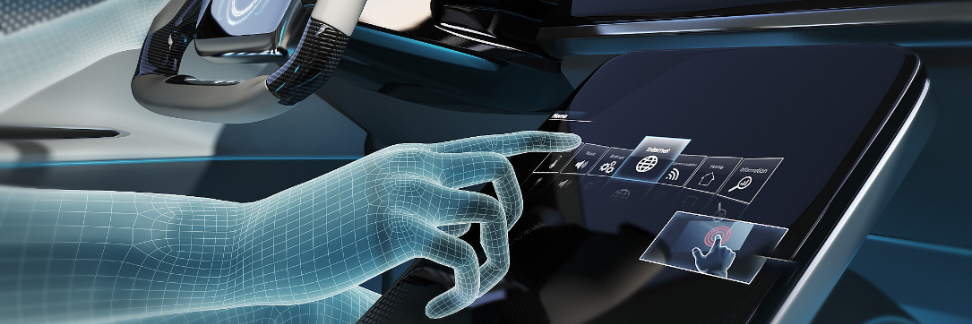

Touchless control on screens with HALIOS® Sensor Interface ICs

Scalable non-contact control with high detection rate - even when disturbed by ambient light, temperature and ageing

The infrared-based HALIOS® Sensor ICs provides the highest sensitivity and robustness in detecting fast hand movements for enhanced non-contact control. The solution is immune against ambient light enabling robust sensor design and scalable via E909.22.

Elmos: HALIOS® Differential Measurement | Competitor: Absolute Measurement |

|---|---|

| + High sensitivity even with high optical cross talk + Very high robustness against flickering light and high ambient light + Reduced software support due to easy implementation of calibrations procedures | + Good sensitivity without cover – Needs high resolution of the PD signal – Needs good temperature drift and offset compensation – Needs additional component for integration – Needs additional control unit for multiple sensor chain |

Simple System9” Sensor bar

|

Performance System13” Sensor bar

|

High End System15” Sensor bar

|

|

|

|

9” Screen control

|

13” Screen control

|

15” Screen control

|

The area required for the sensors on the board is 10 x screen width mm².

The LEDs and photodiodes are arranged in a row. The row consists of so-called HALIOS® cells. Each HALIOS cell includes two LEDs, a photodiode and a compensator. The sequence is LED--PD-C-LED—LED.

We recommend a distance of 34 mm between LEDs and photodiodes. The distance can be varied by +/- 3mm to match the sensor length to detection area.

The distance between the cells should be the same as between the LED and the photodiode in the cell.

The transmittance of the sensor cover should be at least 80% at 940nm. The thickness of the cover should be less than 4 mm and the air gap between sensor and cover less than 3 mm.

A spot sensor can also be operated with the covers that do not meet the minimum requirements, but a reduction in sensor range must be expected.

The usual pollution such as fingerprints are automatically calibrated out and have no influence on the functionality of the sensor.

If you have any questions, don't hesitate to contact us